EDGEWISE COIL

Edgewise Coils Produced by URATANI ENGINEERING

Conventional coils typically use round wire, but they have weaknesses. For example, they inevitably produce wasted space, and more easily accumulate heat due to shape issues.

A coil that eliminates these weaknesses is the edgewise coil, which uses flat wire that is wound edge-wise — bent around its edge side.

This section describes the edgewise coils that URATANI ENGINEERING can manufacture, and introduces some of the features of edgewise coils.

What is an edgewise coil?

Edgewise coil is the generic term for a coil that uses a flat wire instead of a conventional wire, which is wound into a coil around its edge (the shortest side) in the hard-to-bend direction.Edgewise coils are more difficult to produce, and are generally more expensive with longer delivery lead times.

However, by using state-of-the-art 3D CAD systems and winding machines developed in-house, URATANI ENGINEERING is able to propose and manufacture high-precision edgewise coils at low cost and with short delivery lead times.

Features of Edgewise Coils and Comparison

With Conventional Coils

| More compact with improved performance | Heat dissipation |

|---|---|

| The space factor can be increased to 70-80% to eliminate wasted space and offer vastly improved performance compared with a conventional coil occupying the same space. | The characteristic way in which an edgewise coil is wound enables the cross-sectional area to be increased.As a result, temperature rises within a device are reduced, leading to improved heat dissipation. |

| High Frequency | Withstand Voltage and Heat Resistance |

|---|---|

| When an edgewise coil is used, it can be designed to have fewer folds, and the increased surface areas allows high frequencies to be sustained.This results in improved device performance. | Compared with other products such as conventional round wire coils, the way in which an edgewise coil is wound offers superior withstand voltage and heat resistance. |

More compact with improved performance

| Round wire coil | Flat-wound coil using flat wire | Edgewise coils |

|---|---|---|

|

As the cross-section of the coil is round, unnecessary space inevitably forms. This produces a space factor of 50-60%, requiring the use of a bobbin to fill the unneeded space. |

Although the space factor can be increased compared with a round wire coil, unnecessary space still forms. Although it is not necessary to insert a bobbin, efficiency is reduced proportional to the unneeded space. |

Since the cross-section of the coil is rectangular, the space factor is higher than a conventional coil, and can be increased to 70-80%. In addition, it is no longer necessary to insert a coil bobbin in order to reduce unnecessary space. |

Pick upEdgewise coils

offering higher space

When an edgewise coil is used, unlike with a conventional round wire coil the cross section is rectangular, which results in an improved space factor.In addition, the need for a bobbin is eliminated, and unneeded space is not formed.For this reason, if the same power as a round-type coil is maintained, an edgewise coil can be made smaller.Similarly, if the same space is occupied by an edgewise coil instead of a round type, it leads to increased power.

Heat dissipation

| Round wire coil | Flat-wound coil using flat wire | Edgewise coils |

|---|---|---|

|

*1 As multi-layer winding is necessary when using a round wire coil, it becomes easier for heat to accumulated in the unneeded space created by the multi-layer winding. As this produces a temperature difference between the internal and external conductors, functioning of the equipment may be degraded. |

While a flat-wound coil using flat wire can improve heat dissipation over a round wire coil, a large amount of heat can be produced near the core. *1 For this reason, a temperature difference between the internal and external conductors can develop, leading to degraded functioning of the equipment. |

Generally, when an edgewise coil is used it is wound in a single layer, which increases its cross-sectional area. As a result, heat dissipation is improved, reducing the accumulation of heat within a device. |

Pick upThe Large Cross-sectional Area of

Edgewise Coils

The biggest feature of an edgewise coil is in the special way it is wound.Due to the way it is wound, the cross-sectional area of an edgewise coil is increased, and higher heat dissipation than other coils is attained as a result.

As heat dissipation from the core section is reduced compared with conventional coils, the heat is less likely to degrade the performance of the equipment in which the coil is used.

Pick upSustaining high frequencies by reducing the number of folding sections and increasing surface area

When a large current flows through the coil, much of the current flows through the surface sections of the coil, and not a lot flows through the center sections.This may degrade the efficiency of the equipment.

By using an edgewise coil, the number of folding sections of the coil is reduced, which allows the design of coils with a greater surface area.

Withstand Voltage and Heat Resistance

| Round wire coil | Flat-wound coil using flat wire | Edgewise coils |

|---|---|---|

|

As round wire coils have lower withstand voltage and head resistance, they are more susceptible to the effects of voltage and heat during use. Depending on the use of the equipment, this can lead to a greater risk of equipment failure, among other risks. |

While withstand voltage and heat resistance are both improved compared with round type coils, they are still lower than edgewise coils. Considering the effects of voltage and heat, the risks are slightly higher. |

Edgewise coils have superior withstand voltage to coils made with winding methods such as conventional round wire, due to the special winding method employed. In addition, since heat resistance is also improved, there is a reduced risk of heat-induced degraded performance or failure. |

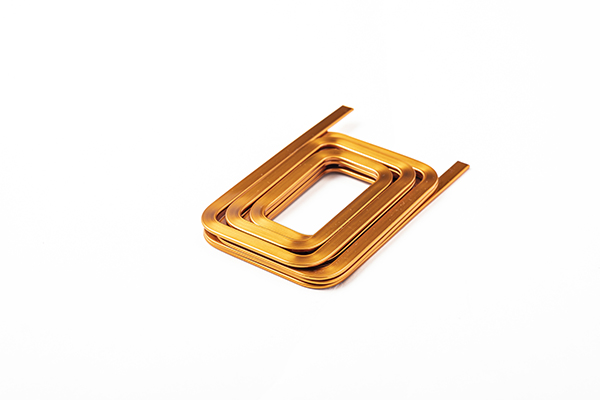

Examples of Edgewise Coil Manufacturing

| Edgewise coils | Rectangular Edgewise Coil | Trapezoidal Edgewise Coil |

|---|---|---|

|

This is a regular edgewise coil manufactured by winding a flat wire around its edge (the shortest side) in the hard-to-bend direction. Flat wire PEW/2.0t×6.0w |

This is an edgewise coil processed into a rectangular shape to match the device into which the coil is installed.We can process coils into shapes that meet your needs. Flat wire AIW/1.5t×6.5w |

Unlike the regular edgewise coil, the coil is formed into a trapezoidal shape to fit the target device by shifting the winding with each turn. Flat wire AIW/0.8t×5.0w |

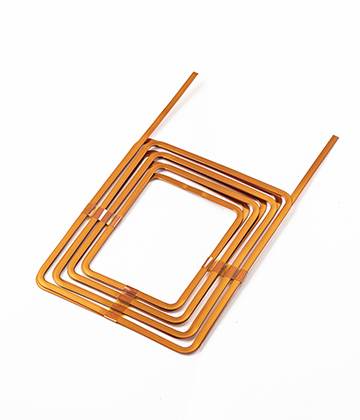

| Consecutively Wound Edgewise Coils | α-Wound Circular Edgewise Coils | α-Wound Rectangular Edgewise Coil |

|---|---|---|

|

These are edgewise coils manufactured by winding four coils in a row.As either left- or right-winding is supported, you can select the type that fits the target equipment. Flat wire AIW/0.8t×5.0w |

This is an edgewise coil employing a type of winding that leaves both the start and end of the wind on the outside.It is used in products such as IH cooking heaters. Flat wire PEW/0.3t×2.5w |

This is an edgewise coil employing a type of winding that leaves both the start and end of the wind on the outside.It is used in devices in which space needs to be conserved. Flat wire PEW/0.8t×4.0w |

| Small Edgewise Coil | Large Edgewise Coils | Twisted Edgewise Coil |

|---|---|---|

|

For use in small devices such as smartphones, we manufacture precision edgewise coils as small as 1 mm. Flat wire PEW/0.25t×0.5w |

We also handle large edgewise coils between 1,500 and 2,000 mm in size for use in large facilities such as power plants, ships and rail. |

In cases such as when there is insufficient installation space for a regular edgewise coil, we can also manufacture edgewise coils with a twisted type of deformed shape. |

Please contact us by telephone or fill out the email inquiry form for any consultations or inquiries regarding URATANI ENGINEERING coils and motors.We stand ready to propose original products that will meet your needs.

- HIDEYUKI OTA (+1)270―889-8774

- uratani-usa@uratani-eng.com

- KIYOTAKA KANZAWA +49 (0)162-3268-891

- uratani-europe@uratani-eng.com

Please click the following link to make an inquiry using the email form.As we can develop proposals to suit your requirements, please feel free to include any relevant information about your coil-related issues.

Information on how to contact URATANI ENGINEERING for consultations or inquiries is given here.